The cuplock scaffolding is a supporting system that uses specially designed cuplocks to connect horizontal ledgers and vertical standards. Its core structure involves the lower half of cuplock being welded to the vertical standard, the upper half inserted around onto the vertical standard and being capable of sliding up and down. During assembly, the wedge heads of horizontal ledgers and vertical standards are inserted into the lower half cuplock, and the upper half is fixed by spacer after pressed and rotated, achieving the connection of tubes. Due to the characteristics of simple structure, convenient assembly and disassembly, high safety and reliability, it’s particularly suitable for various large and medium-sized construction scenarios of architectural engineering, bridges, tunnels, and comes into one of the widely used system-type scaffolds in current construction.

The basic components of cuplock scaffolding system include main components such as horizontal ledger, vertical standard, diagonal brace, adjustable base jack, as well as auxiliary components covering joint pin, plank, stairway, top head jack and outer-rigger.

Cuplock horizontal ledger |

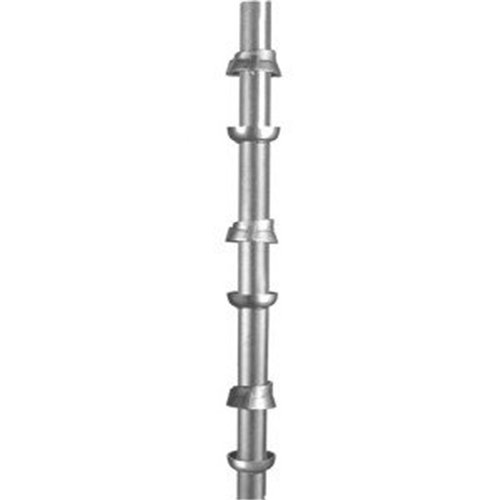

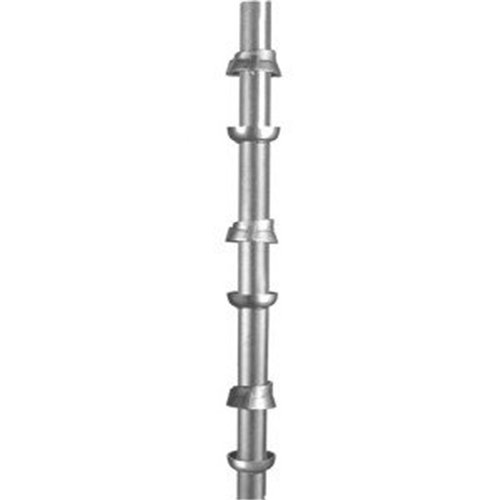

Cuplock vertical standard |

Cuplock diagonal brace |

Stairway |

Adjustable base jack |

Joint pin |

Plank |

Top head jack |

Outer-rigger |

Application Scope

● Housing construction: Widely used in the construction of internal and external scaffolding of high-rise buildings, as well as the support of large-span spatial structures. Especially for the construction of super high-rise building core tubes, cuplock scaffolding can provide a stable support system.

● Bridge engineering: Can be used in the construction of bridge piers, abutments, and beam bodies, providing working platforms and supports for workers and materials. In particular for the construction of elevated bridges, cross-sea bridges.

● Tunnel engineering: During the excavation and lining of tunnels, cuplock scaffolding can be used to build construction platforms and support structures to ensure construction safety and smooth progress.

● Other projects: Applied to the construction of water towers, chimneys, large-span scaffolds, storage shelves, etc., as well as the temporary facilities for exhibitions, concerts.

Compare to Other Types of Scaffolding

Type | Core strength | Main applied project |

Ringlock scaffolding | Low cost, simple maintenance, low requirements for the foundation | Small and medium-sized projects and high-rise buildings with limited budgets |

Kwikstage scaffolding | Strong bearing capacity, good durability, excellent lateral displacement resistance capability | Scenarios involving large-span beam pouring , heavy equipment support with high loads |

Door frame scaffolding | Adaptable to irregular structures, with significant advantages in height and load-bearing capacity. | Construction of super high-rise building core tube, elevator shaft, and curved walls |